We use best-in-class technologies

And adapt the scale and platform to your needs

Our manufacturing technology

Exothera uses Univercells’ advanced platforms alongside other industry-leading technologies to design high-quality, cost-effective viral vector processes tailored to the requirements of our customer’s particular therapy. We can design platform with upstream and downstream best-in-class technologies for both adherent and suspension cell culture.

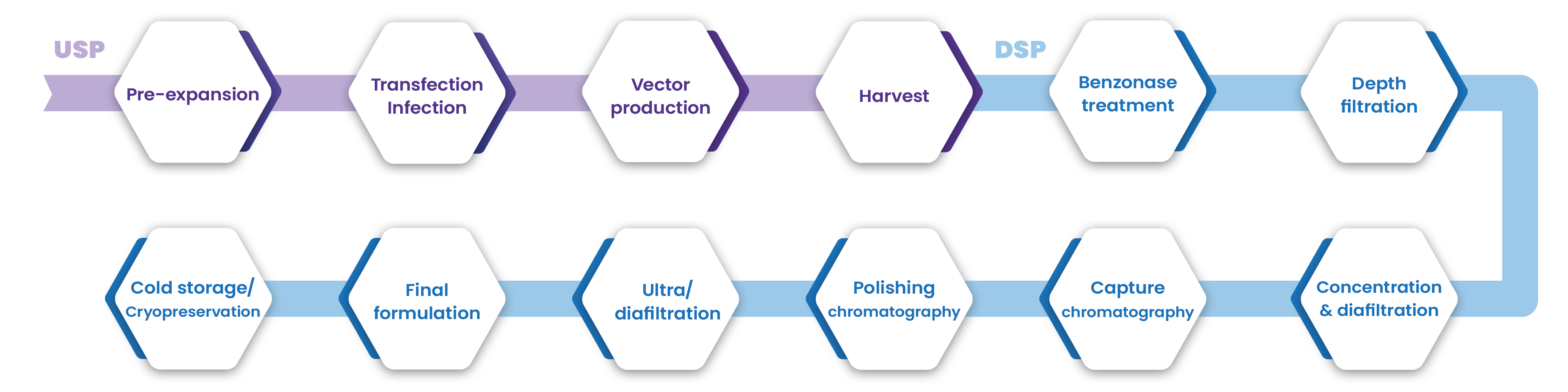

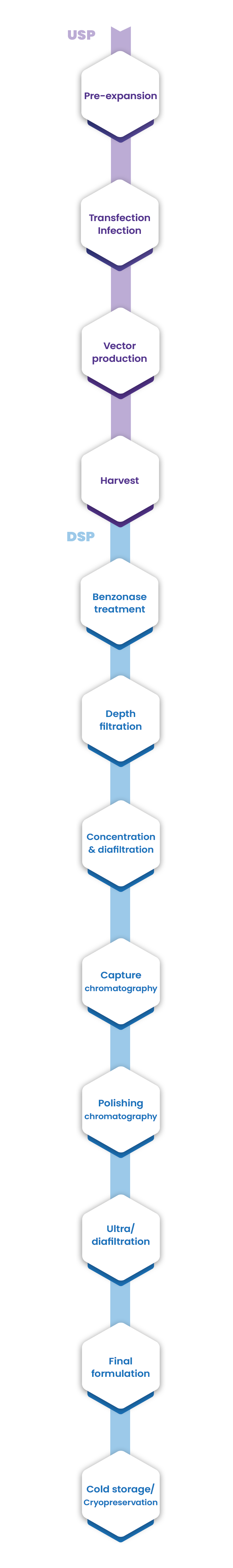

Drug substance process flow

The Upstream Process

Our team has more than 20 years of cell culture experience. It has led several AAV projects and has a lot of expertise with all type of viruses: AAV, Adenovirus, Lentivirus, Influenza, Polio, Herpes virus, etc. Exothera can set up your adherent and suspension processes in fixed-bed or stirred tank bioreactors.

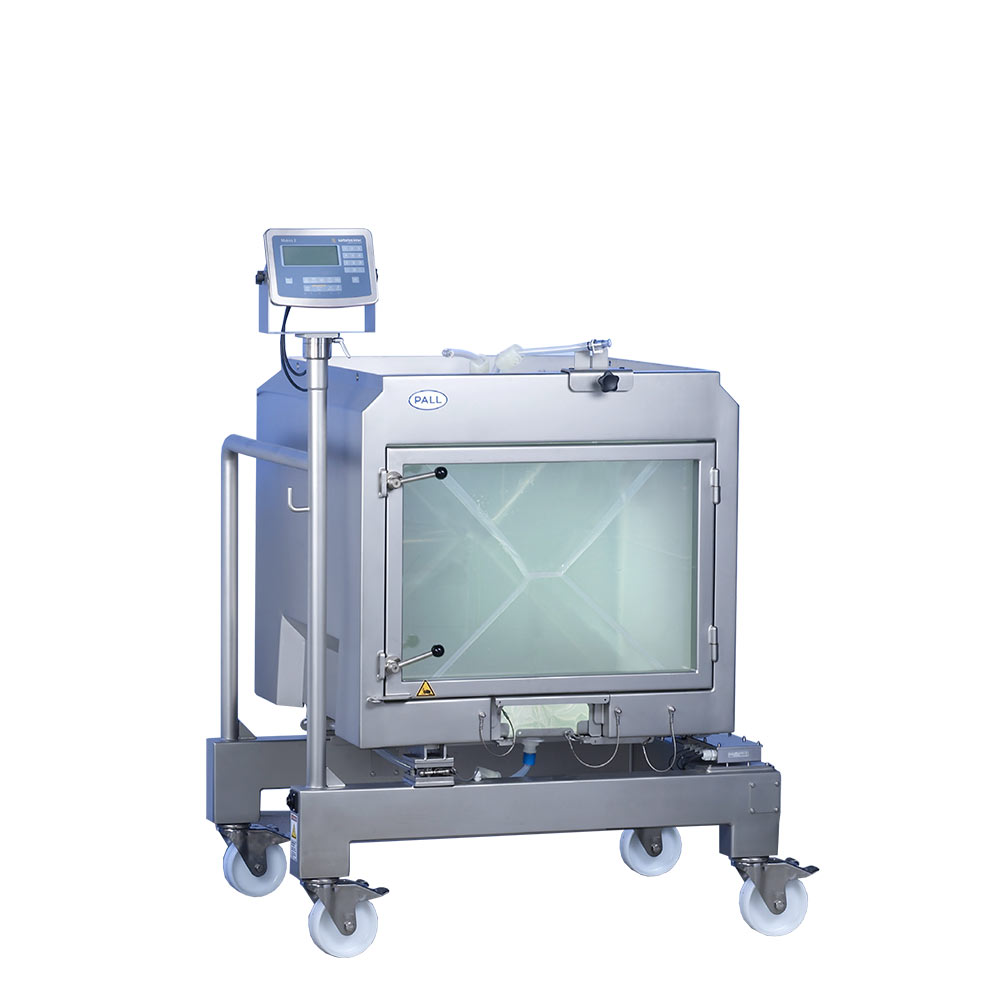

For our adherent and suspension processes, we work with the equipment of the Univercells Technologies company. For adherent processes, we also use the iCELLis® bioreactor. It is the automated, single-use, fixed-bed bioreactor from Pall Corporation.

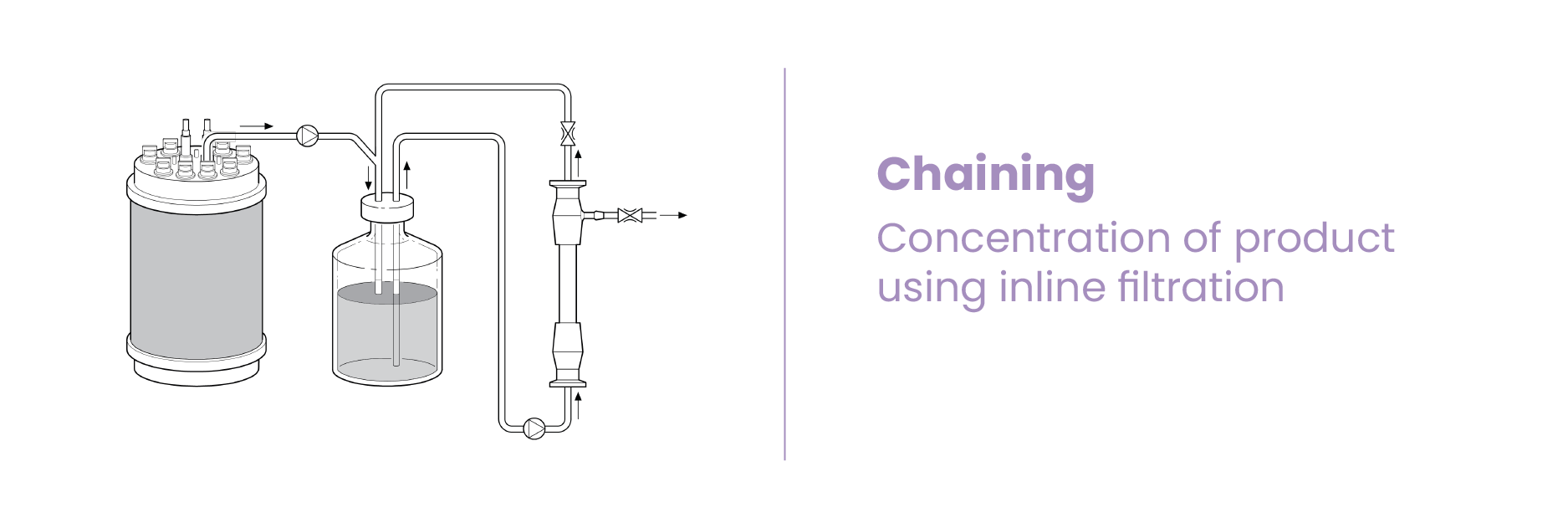

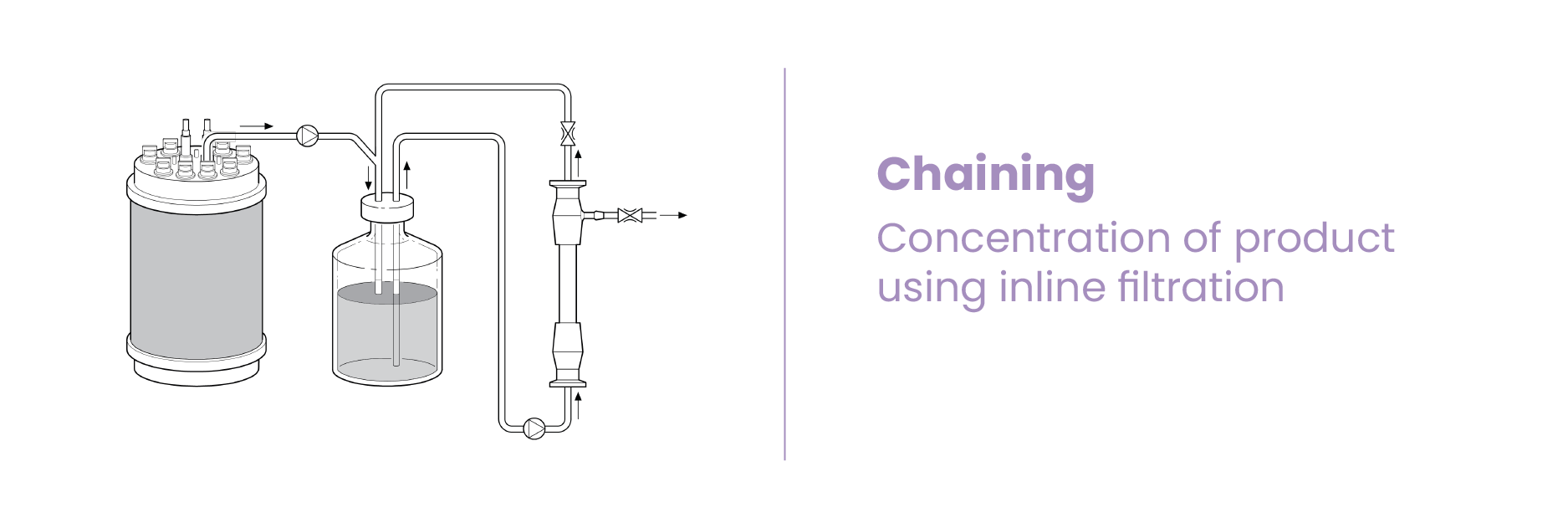

The scale-X™ platform

Featuring a structured and intensified fixed-bed design, scale-X™ bioreactors are chained with in-line product concentration. They offer predictable scalability from R&D to GMP while accommodating a range of viral targets, offering the flexibility and performance essential to a CDMO.

Our suspension-based manufacturing platform are established on a range of different sizes stirred tank single-use bioreactors from Pall Corporation, including Allegro™ STR single-use bioreactors series. These bioreactors deliver consistent and scalable cell culture performance across the range. From the outset of the design, our technology places strong emphasis toward providing a compact, ergonomic and intuitive turnkey bioreactor design concept to maximize usability and process assurance, while maintaining optimal performance needed in a cell culture environment through several easy and intuitive operation features.

Sartorius wave biorector RM 50 & RM 200

Allegro STR Single-Use Bioreactor

Allegro STR Single-Use Bioreactor

The Downstream Process

Exothera’s team has more than 20 years of DSP experience and is highly competent in purification of mABs, AAVs, adenoviruses, retroviruses, vaccines, and Exosomes. Our DSP platforms are composed of a range of technologies for clarification, concentration, chromatography, formulation, and continuous purification.

Chromatography

Our manufacturing platforms

Exothera uses Univercells’ advanced platforms alongside other industry-leading technologies to design high-quality, cost-effective viral vector processes tailored to the requirements of our customer’s particular therapy. We can design platform with upstream and downstream best-in-class technologies for both adherent and suspension cell culture.

Drug substance process flow

The Upstream Process

Our team has more than 20 years of cell culture experience. It has led several AAV projects and has a lot of expertise with all type of viruses: AAV, Adenovirus, Lentivirus, Influenza, Polio, Herpes virus, etc. Exothera can set up your adherent and suspension processes in fixed-bed or stirred tank bioreactors.

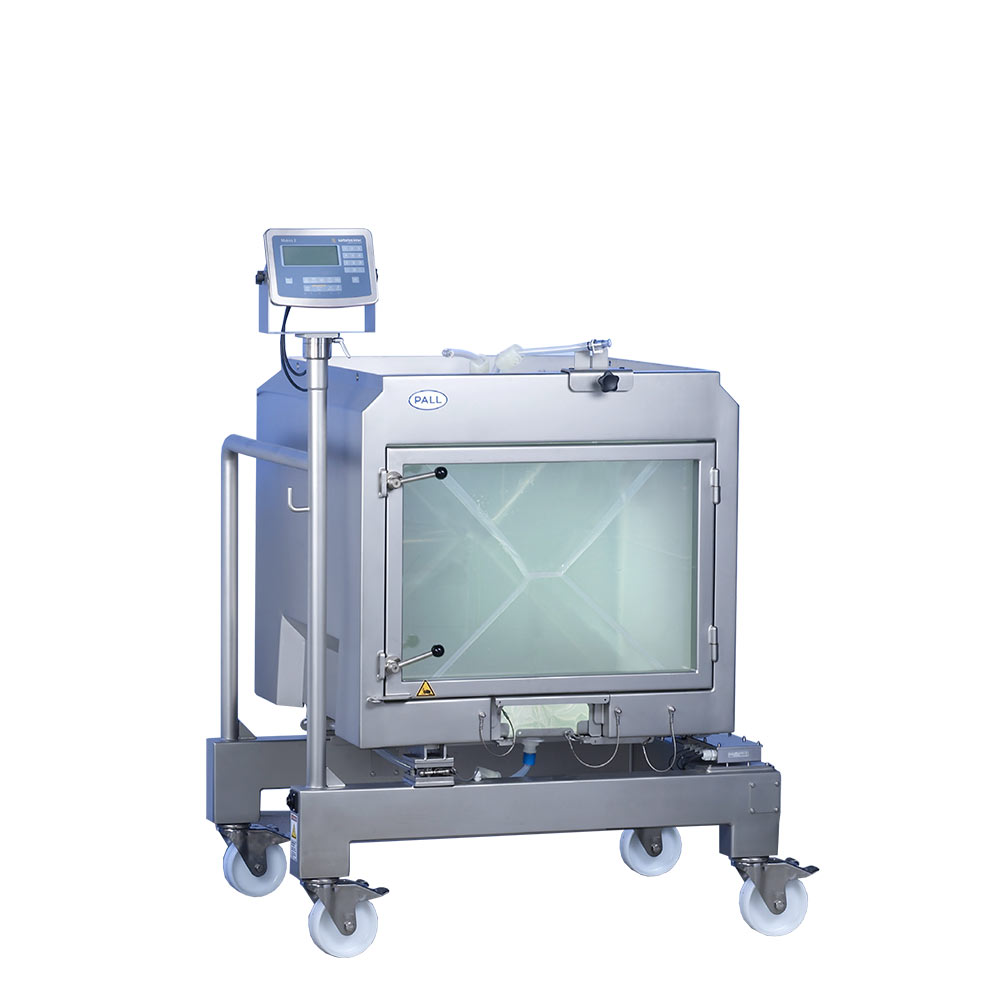

For our adherent and suspension processes, we work with the equipment of the Univercells Technologies company. For adherent processes, we also use the iCELLis® bioreactor. It is the automated, single-use, fixed-bed bioreactor from Pall Corporation.

The scale-X™ platform

Featuring a structured and intensified fixed-bed design, scale-X™ bioreactors are chained with in-line product concentration. They offer predictable scalability from R&D to GMP while accommodating a range of viral targets, offering the flexibility and performance essential to a CDMO.

Benchtop

NevoLine

Our suspension-based manufacturing platform are established on a range of different sizes stirred tank single-use bioreactors from Pall Corporation, including Allegro™ STR single-use bioreactors series. These bioreactors deliver consistent and scalable cell culture performance across the range. From the outset of the design, our technology places strong emphasis toward providing a compact, ergonomic and intuitive turnkey bioreactor design concept to maximize usability and process assurance, while maintaining optimal performance needed in a cell culture environment through several easy and intuitive operation features.

Sartorius wave biorector RM 50 & RM 200

Allegro STR Single-Use Bioreactor

Allegro STR Single-Use Bioreactor

The Downstream Process

Exothera’s team has more than 20 years of DSP experience and is highly competent in purification of mABs, AAVs, adenoviruses, retroviruses, vaccines, and Exosomes. Our DSP platforms are composed of a range of technologies for clarification, concentration, chromatography, formulation, and continuous purification.

Chromatography