POSTER

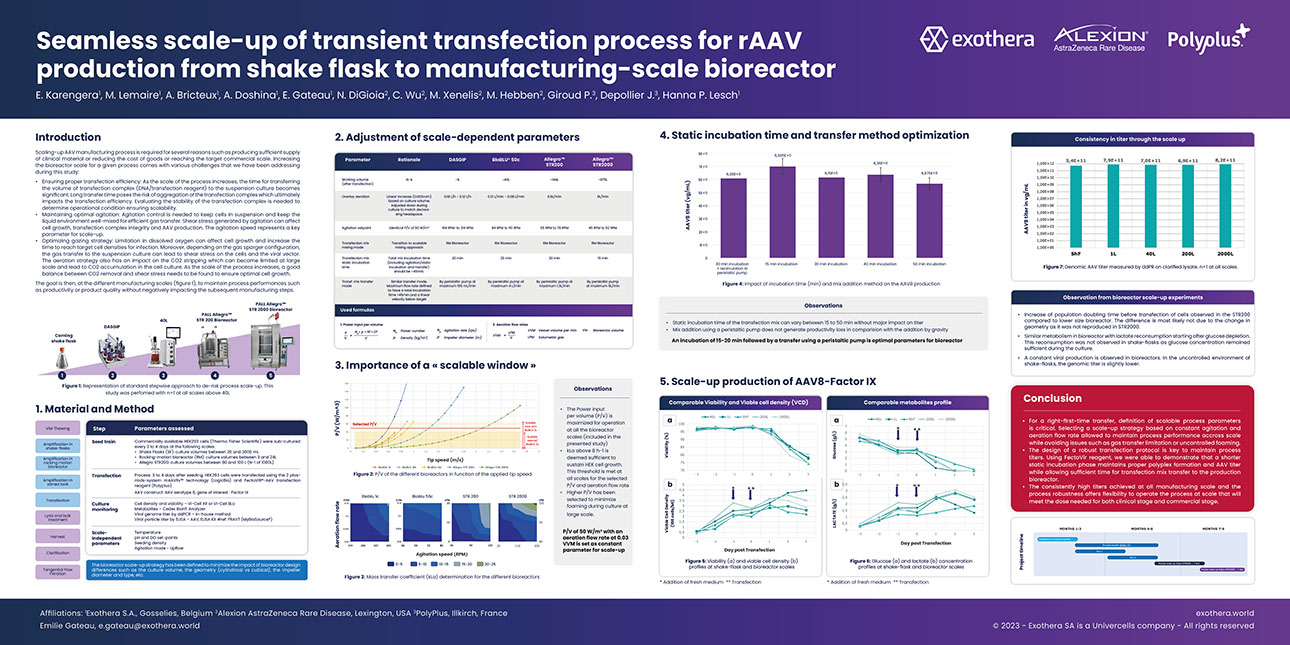

Seamless scale-up of transient transfection process for rAAV production from shake flask to manufacturing-scale bioreactor

E. Karengera, M. Lemaire, A. Bricteux, A. Doshina, E. Gateau, N. DiGioia, C. Wu, M. Xenelis, M. Hebben, Giroud P., Depollier J., Hanna P. Lesch

Abstract

Scaling-up AAV manufacturing process is required for several reasons such as producing sufficient supply of clinical material or reducing the cost of goods or reaching the target commercial scale. Increasing the bioreactor scale for a given process comes with various challenges that we have been addressing during this study:

- Ensuring proper transfection efficiency: As the scale of the process increases, the time for transferring the volume of transfection complex (DNA/transfection reagent) to the suspension culture becomes significant. Long transfer time poses the risk of aggregation of the transfection complex which ultimately impacts the transfection efficiency. Evaluating the stability of the transfection complex is needed to determine operational condition ensuring scalability.

- Maintaining optimal agitation: Agitation control is needed to keep cells in suspension and keep the liquid environment well-mixed for efficient gas transfer. Shear stress generated by agitation can affect cell growth, transfection complex integrity and AAV production. The agitation speed represents a key parameter for scale-up.

- Optimizing gazing strategy: Limitation in dissolved oxygen can affect cell growth and increase the time to reach target cell densities for infection. Moreover, depending on the gas sparger configuration, the gas transfer to the suspension culture can lead to shear stress on the cells and the viral vector. The aeration strategy also has an impact on the CO2 stripping which can become limited at large scale and lead to CO2 accumulation in the cell culture. As the scale of the process increases, a good balance between CO2 removal and shear stress needs to be found to ensure optimal cell growth.

The goal is then, at the different manufacturing scales, to maintain process performances such as productivity or product quality without negatively impacting the subsequent manufacturing steps.