The only CDMO in the world to offer continuous-batch RNA manufacturing services

Enabling production of the highest quality RNA for vaccines and therapeutics at high speed and low CoGs

Manufacturing process

We use our ExoREADY platform to produce the fastest and most efficient clinical product to support your results analysis. We produce linear DNA stocks, purified mRNA and encapsulated mRNA, following GMP requirements.

We can produce GMP-like lots when non-GMP conditions are required from toxicology, through all clinical phases and commercial scale products.

We use one optimized manufacturing process for R&D as well as for GMP use, removing the need for process development or scale-up. This ensures a higher quality product and significantly speeds time to market, all while reducing CoGs.

Our approach and expertise

Starting from a cell-free working bank, we only need a few days to obtain the linear DNA template for mRNA production without fermentation, or plasmid linearization.

Afterwards, ExoREADY uses an optimized in-vitro transcription method to obviate the need for downstream dsRNA clearance. Our optimal process reduces the consumption of capping reagents without sacrificing capping yield and requires fewer purification steps while still guaranteeing high quality.

High-quality, High-speed production

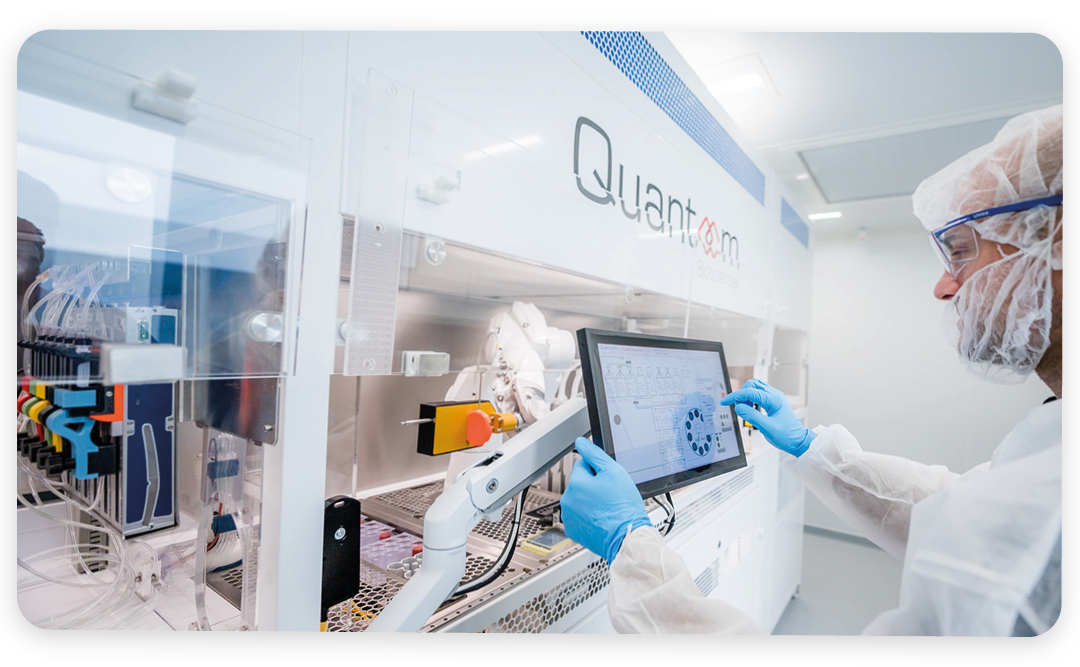

For our RNA product manufacturing, Exothera uses the Ntensify™ equipment, which is already at its final scale during non-GMP manufacturing, speeding up considerably your product development.

ExoREADY uses automated process step operations that are based on the principles of intensification and chaining. This means that production is consistent and can be adapted for multiple different purposes simply by re-programming the used equipment, ensuring a high-quality, high-speed production.

Thanks to our optimal process, we are able to produce up to 5g purified RNA/day (up to 500k doses per day) for clinical manufacturing.

Ntensify™ Midi

For any additional information

Please contact us and we will respond quickly!

Manufacturing process

We use our ExoREADY platform to produce the fastest and most efficient clinical product to support your results analysis. We produce linear DNA stocks, purified mRNA and encapsulated mRNA, following GMP requirements.

We can produce GMP-like lots when non-GMP conditions are required from toxicology, through all clinical phases and commercial scale product.

We use one optimized manufacturing process for R&D as well as for GMP use, removing the need for process development or scale-up. This ensures a higher quality product and significantly speeds up time to market, all while reducing CoGs.

Our approach and expertise

Starting from a cell-free working bank, we only need a few days to obtain the linear DNA template for mRNA production without fermentation, nor plasmid linearization.

Afterwards, ExoREADY uses an optimized in-vitro transcription method to obviate the need for downstream dsRNA clearance. Our optimal process reduces the consumption of capping reagents without sacrificing capping yield and requires fewer purification steps while still guaranteeing high quality.

High-quality, High-speed production

For our RNA product manufacturing, Exothera uses the Ntensify™ equipment, which is already at its final scale during non-GMP manufacturing, speeding up considerably your product development.

ExoREADY uses automated process step operations that are based on the principles of intensification and chaining. This means that production is consistent and can be adapted for multiple different purposes simply by re-programming the used equipment, ensuring a high-quality, high-speed production.

Thanks to our optimal process, we are able to produce up to 5g purified RNA/day (up to 500k doses per day) for clinical manufacturing.

Ntensify™ Midi