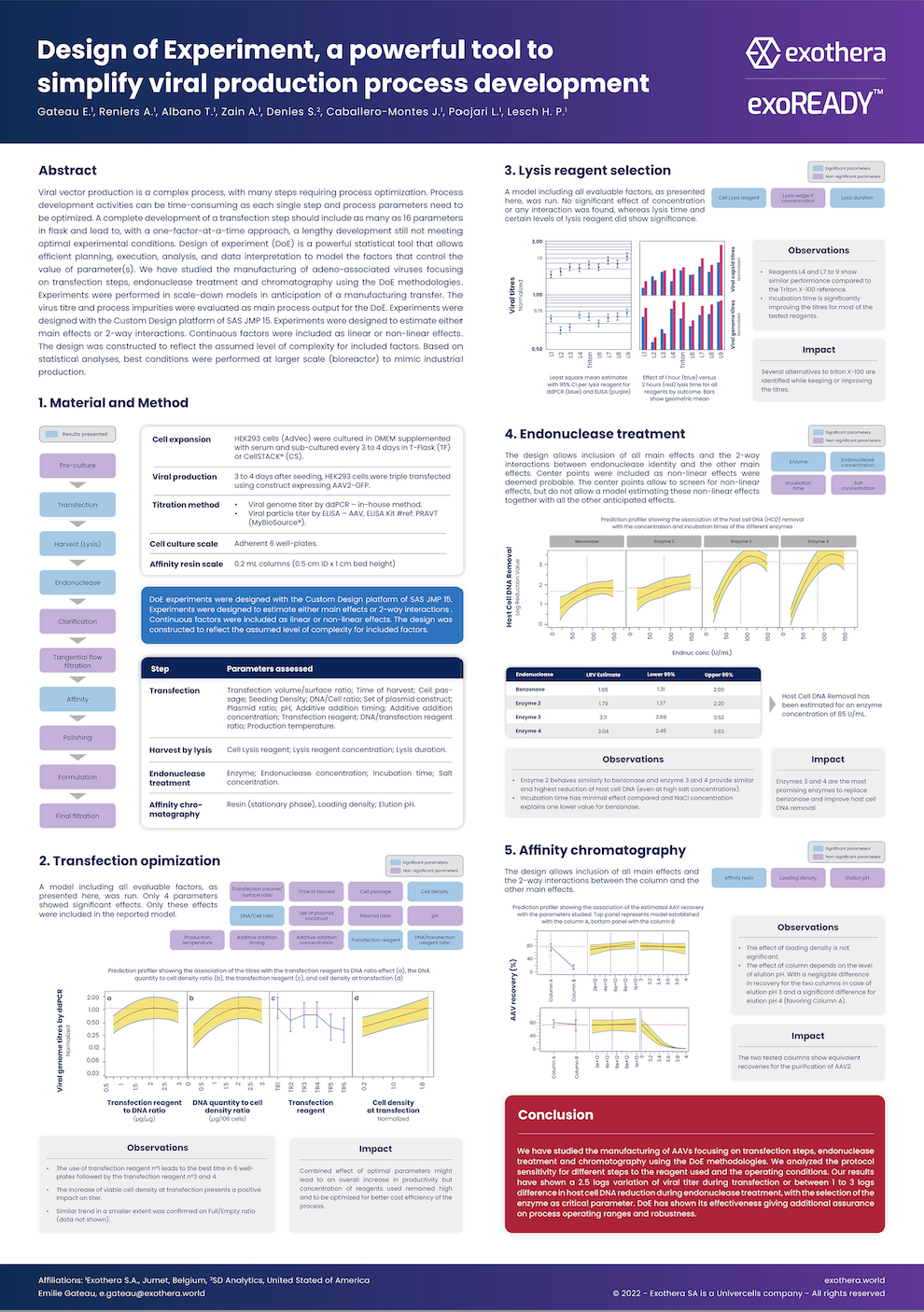

POSTER

Design of Experiment, a powerful tool to simplify viral production process development

Gateau E., Reniers A., Albano T., Zain A., Denies S., Caballero-Montes J., Poojari L., Lesch H. P.

Abstract

Viral vector production is a complex process, with many steps requiring process optimization. Process development activities can be time-consuming as each single step and process parameters need to be optimized. A complete development of a transfection step should include as many as 16 parameters in flask and lead to, with a one-factor-at-a-time approach, a lengthy development still not meeting optimal experimental conditions. Design of experiment (DoE) is a powerful statistical tool that allows efficient planning, execution, analysis, and data interpretation to model the factors that control the value of parameter(s). We have studied the manufacturing of adeno-associated viruses focusing on transfection steps, endonuclease treatment and chromatography using the DoE methodologies. Experiments were performed in scale-down models in anticipation of a manufacturing transfer. The virus titre and process impurities were evaluated as main process output for the DoE. Experiments were designed with the Custom Design platform of SAS JMP 15. Experiments were designed to estimate either main effects or 2-way interactions. Continuous factors were included as linear or non-linear effects. The design was constructed to reflect the assumed level of complexity for included factors. Based on statistical analyses, best conditions were performed at larger scale (bioreactor) to mimic industrial production.