Contract Development and Manufacturing Organizations (CDMOs) offer ready-to-go platforms to solve the viral vectors and vaccines manufacturing capacity bottleneck. These platforms can help biotherapeutics developers to reach clinical trials with a consistent, regulatory-compliant and affordable product. However, CDMOs impose long-term binding contracts, forcing clients to commit to the platform until the late clinical stage, unless they pay costly licensing fees.

At Exothera, we are designing a flexible viral vector platform that will offer our partners and customers a variety of collaboration options, adaptive solutions, and affordable licensing fees based on a checkpoint system that could help clients to choose their path at each stage without long-term binding contracts.

Experts

- Dirk Geerts, Senior Development Scientist at Glycostem Therapeutics.

- Sanjin Zvonić. Vice President, Business Development & Practice Expert at Dark Horse Consulting.

- Hanna P. Lesch, Chief Technology Officer at Exothera.

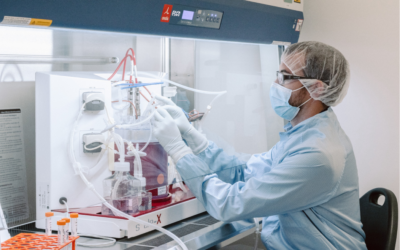

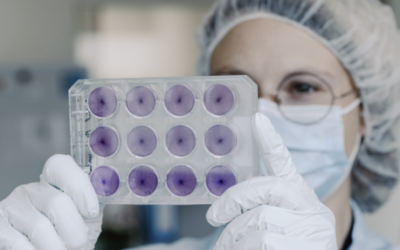

The growing need for viral vectors and vaccines has resulted in a manufacturing capacity bottleneck and new products development slowdown. Contract Development and Manufacturing Organizations (CDMOs) are investing to solve these issues and are increasingly offering ready-to-go platforms for the rapid development of biotherapeutics.

Most CDMOs retain the rights to these platforms with long-term binding contracts that force the client to commit to the platform until scale-up for late clinical stage development or production. There is either no tech transfer option to move production to the client or it requires the payment of complex, expensive licensing fees.

At Exothera, we are designing a flexible viral vector platform that will offer our partners and customers a variety of collaboration options, adaptive solutions, and affordable licensing fees based on a checkpoint system that could help clients to choose their path at each stage without long-term binding contracts.

We spoke to industry experts and our own CTO, Hanna Lesch, to find out how they think this could change the CDMO selection process for biotherapeutic developers.

Selecting a CDMO

Question: Choosing the right CDMO to outsource your product development to is crucial for the success of a new biotherapeutics. What do you look for to be confident that a CDMO will be a suitable partner?

DG: Selecting a CDMO can be a painful process. Last year, for instance, we decided to contract with a consultancy firm to help us with the negotiation with different potential partners. We ended up creating a matrix to compare different CDMOs based on available time slots, costs, license fees and the actual technology offered. In the end, we selected the CDMO that showed the highest flexibility in terms of platform and services.

SZ: When I was VP of manufacturing, my dream CDMO was the CDMO that I never had to leave. As a developer, I was looking for a CDMO to whom I could truly outsource at a reasonable fee without engaging my team in micromanaging the CDMO, so I could focus on discovery and development.

In the end, we selected the CDMO that showed the highest flexibility in terms of platform and services. DIRK GEERTS

…my dream CDMO was the CDMO that I never had to leave. SANJIN ZVONIĆ

What are the benefits of a viral vector platoform?

Nowadays, CDMOs can provide a dedicated viral vector platform to fast-track the development and manufacturing of new viral vector-based biotherapeutics. In your opinion, what are the benefits or drawbacks of a ready-to-go platform?

DG: For small trials and early phase products, I think there are only benefits. But if you have a much more advanced project, let’s say phase one or phase two, and you want to switch to commercial manufacturing, ready-to-go platforms are rarely completely suited to your process, and you need to find a solution with the CDMO and that can be a drawback.

SZ: Benefits and drawbacks depend on what stage company you are. If I’m an early-stage company, it allows me to fast track getting to market and minimizes investment. However, I don’t think any CDMO can have a ready-to-go platform that meets 100% of the needs of every customer so you need to compromise sometimes, which can be seen as a drawback for some companies.

HL: The major benefit of ready-to-go platforms is the ability to fast track a product to the clinic cost-efficiently without compromising on state-of-the-art technology, analytical know-how, and regulatory support. Moreover, ready-to-go platforms are highly standardized, which minimizes potential risks and unwanted surprises during process development but is also highly compatible with later clinical phases or commercial scale requirements. However, a high degree of standardization can make the process too rigid if the CDMO is not willing to adjust the platform to meet the client’s requirements. A good ready-to-go platform should provide several solutions for each step of the process to allow room for adjustment without sacrificing the advantages of standardization.

Which characteristics and/or services are essential to offer as part of a ready-to-go viral vector platform?

DG: Having enough technical details to be able to predict the expected yield and productivity is essential. Regulatory support is also crucial. I don’t see a point in having a discussion with a CMDO that doesn’t provide that support as part of the platform.

SZ: I think there are three critical features. First, is what I would call customer engagement. As a CDMO, you need to create trust in your platform. You need to provide a very data-driven case, looking at both the business and the technical aspects, and outlining the advantages and disadvantages of the platform. Another thing that’s going to be important to people is costs, not just in terms of services but also from a cost of goods perspective. A standardized platform can give a CDMO increased purchasing power because they can buy quantities of the same reagents and disposables to provide services to 10 small customers. Thirdly, being able to demonstrate that you not only have the technological capability but also the expertise in using it.

HL: For smaller biotechs to really benefit from a readyto-go viral vector platform, the CDMO needs to be able to offer end-to-end support starting with the selection of raw materials such as the master cell banks and plasmids all the way through to fill and finish. The socalled “one-stop-shop approach” helps the client to reach their goal quickly and cost-effectively without compromising analytical development and regulatory support. This is possible only if the CDMO can guarantee high technology standards and expertise, to fast track the process and minimize risks, and efficient supply chain service, to optimize the cost of goods.

The so-called “one-stopshop approach” helps the client to reach their goal quickly and cost-effectively without compromising analytical development and regulatory support. HANNA P. LESCH

What types of organizations benefit the most from a ready-to-go platform?

SZ: I think with gene therapy, and to a large extent also with cell therapy, how things are made is more important than what it is being made. Organizations with a defined process that are in later stage development could find a ready-to-go platform very interesting. Let’s take a typical customer, somebody who has already launched one product and is now launching another one. Since they have ironed out all the unknown issues and are confident with the process, they can just select a platform and generate data and results. After all, due to the nature of C>, the learning is not only on the clinical side but also on the CMC and manufacturing side.

DG: Ready-to-go platforms are interesting for small companies because they allow them to fast-track small scale trials of new biotherapeutics and generate preliminary CMC and clinical data and then apply for more funding to reach the following checkpoint.

Viral vector platforms are powerful tools, but they often come with a long-term binding contract with the CDMO that owns them. What is the potential impact of this on the later stages of development, for instance, during clinical trials and large-scale manufacturing?

SZ: The commitment to the platform is challenging because even with a thorough assessment of the platform upfront, you might need to change things in the latter stages, not just in terms of clinical development, but also in terms of CMC development. Therefore, CDMOs are incentivized to keep people on the platform to avoid the complexity of managing customer modifications. For some customers, this can be a scary prospect especially if they plan to build their own manufacturing in the future. However, if the CDMO engages in an open and friendly conversation with the client, they can reach an agreement that gives the customer the flexibility to leave. In the end, as a CDMO, if the client needed to drastically change the platform, I would rather just give him the option to leave.

DG: For small companies, being bound to a CDMO can be a major issue. Some CDMOs require a tiein to use their platform up to clinical phase III, after which companies need to pay a royalty, which only bigger companies can afford. Big CDMOs tend to be less responsive and consistent when working with small biotechs which can lead to a sense of frustration and a delay in deliverables. This lack of customer service makes long term binding contracts unappealing.

HL: When you use ready-to-go platforms you need to fix the manufacturing process as early as possible to minimize any changes and unwanted surprises and be able to achieve clinical/marketing approval. However, if there are any problems (such as timing, quality, technical, quality of the service, or business-related issues) it is very difficult for a biotech to “escape” and transfer the platform to another service provider. Of course, it is never good for a CDMO to lose a client but for a client to have no opportunity to leave can be perceived as risky. CDMOs should aim to “lock” their clients in based on the levels of service they provide, not based on a binding contract. If you are confident in the quality of the services that you provide, it’s in your interest to establish a series of checkpoints where you can discuss the next steps with the client without any of the parties feeling obliged to continue. This will change the dynamics of the CDMO-client relationship, basing it on trust and open discussion, rather than contractual obligations.

CDMOs should aim to “lock” their clients in based on the levels of service they provide, not based on a binding contract. HANNA P. LESCH

Tech Transfer & Viral Vector Platforms

Exothera is offering a flexible ready-to-go platform, which can be transferred to the client’s facility after process development in case the client’s long-term manufacturing strategy is to bring production in-house. How do you think biotherapeutics developers might respond to this?

SZ: I think that would be a great option to offer such flexibility to customers. Exothera is challenging the contract manufacturer business model where the best thing for the business is to have a portfolio of customers who are working on your platform, and who are with you out of choice.

DG: I think Exothera’s offer is very interesting. Most biotherapeutics developers want more adaptable, almost custom-made solutions for multiple reasons. First, biotherapeutics developers are usually small companies and they do not have the budget to step into a binding contract from phase one to commercial manufacturing. Second, the CDMO field is developing rapidly. Exothera is a perfect example. Third, the virus manufacturer technology is changing a lot, especially concerning things like cell lines, medium composition, and downstream processing. The last reason is the nature of C> projects, where after phase one you have about an 80% chance that you will not go further, due to lack of funds or disappointing phase one results, so being tied to a CDMO means that you have no exit strategy.

HL: At Exothera, we believe in helping biotechs to make life-changing therapies available for all. We are changing the business model of how we work with clients to develop their therapies by offering a flexible viral vector platform. We believe that for more cell and gene therapies to reach the market successfully, biotechs need access to lower cost platforms that help them reach the clinic more quickly. They also need to have the flexibility to bring manufacturing in-house if, for example, they are acquired by a larger company that already has this capability. Biotechs that can demonstrate this are likely to have a higher market valuation.

Conclusion

The ability of CDMOs to provide flexible ready-to-go platforms represents a change of operating model which will allow biotherapeutic companies quicker and lower cost access to production capacity and more freedom to select the manufacturing set-up that best suits them – either in-house or outsourced. CDMOs will no longer be protected by binding contracts and will need to up their game to provide higher levels of service to retain clients. This is going to drive an increase in quality standards and agility and thus speed up the process to bring life-changing cell and gene therapies to patients.